Profile:

This machine is a high technical equipment with successfully and designed by introducing into advanced overseas technology and integrating GMP requirement,with features of fair structure,full function, easy operation,accurate filling,stable running,as well as low noise.It adopts with PLC controller.automatically operating from liquid or high viscosity material filling till batch number printing (include manufacture date),it's an ideal equipment for Alu tube,plastic tube and multiple tube filling and sealing in cosmetic,pharmacy.foods,adhesives etc,comply with the standard of GMP.

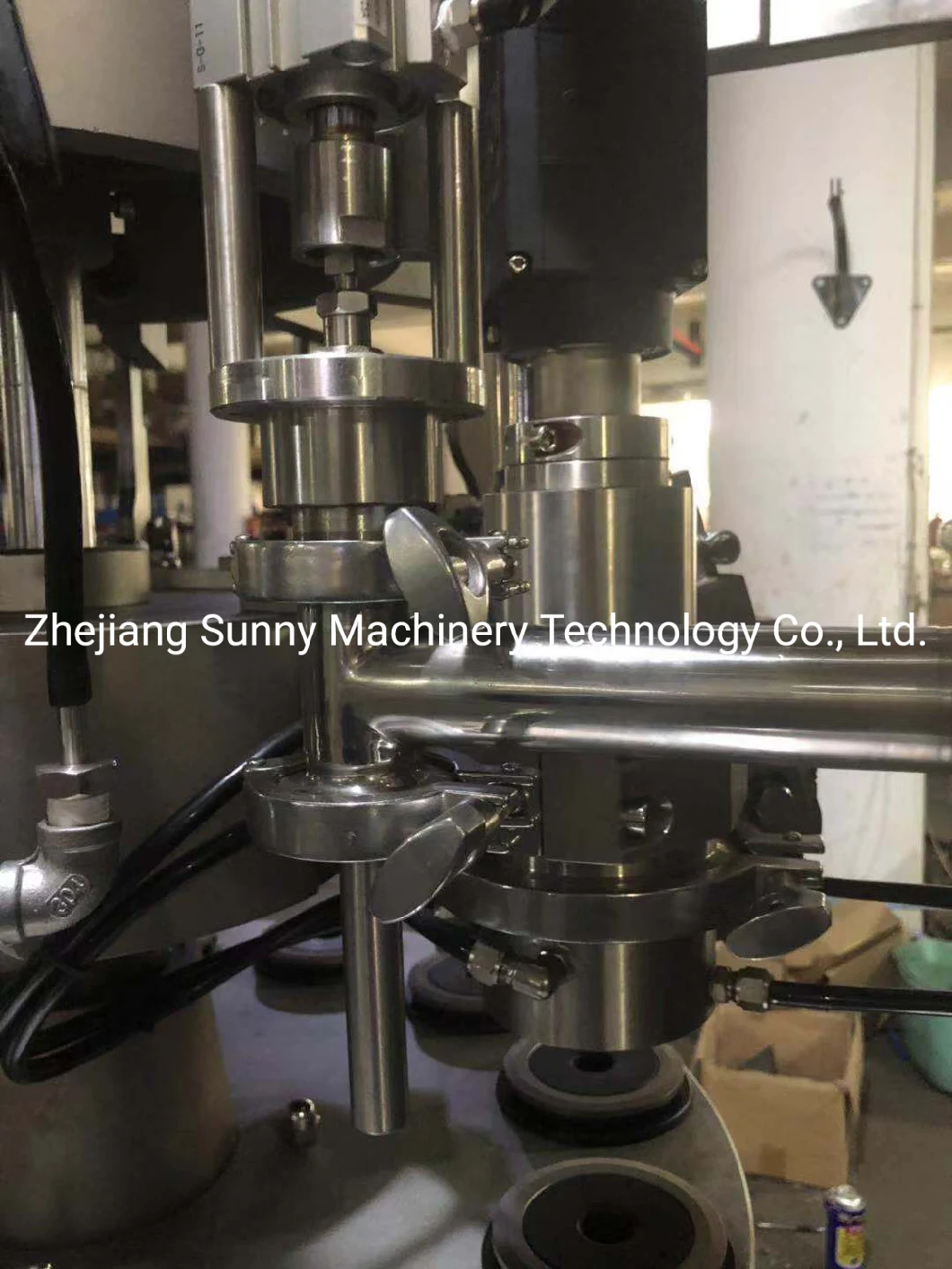

Main features:

(1)stepless speed regulating, parameters of the grasping device equipment, production count statistics, pressure indicator, fault indication, health, making operation simple and user-friendly.

(2)Automatic completion of feeding tube, color sensor, filling, sealing, marking, export of finished products the whole process.

(3)High precision calibration system, reduces the chromatic aberration of tube and color range.

(4) Digital display, adjust fast, accurate (for multiple specifications and multiple variety production).

(5)Integration of mechanical, optical, electrical, gas,if the tube not at his right position and low atmospheric pressure, automatic display ,the machine will alarm, when open the protective door,the machine can shut down automatically.

The difference between our machine and the machine of other manufacture:

1.Besides of the motor of feeding tube,we add a rail bearing to move to make sure the tube can drop smoothly.

2 We use the cylinder to press the tube to the right position ,To avoid the material waste caused by tube does not reach the designated position.

3.There is enough time for eye marking,the pulse make the eye marking stable.

4.About the tube-holding base we use a mechanical interlocking to avoid the tube-holding base slipping in a high speed rotation .Other manufacture use magnetic .

5 The sealing place use "LESITER" ( Switzerland) hot air system to heating the tube, and the sealing is beautiful.

6:the filling piston parts we use ceramic istead of stainless steel. The stainless steel need to clean and replace very ofen. Our ceramic piston can be used forever. It saves a lot time. Other manufacture use the stainless steel.

7: For the plastic tube,we added a function to trim the tail to make sure the tail to be neat and beautiful.

8: All of our electrical parts use OMRON, DELTA, MITSUBISHI and so on,and the cylinder make to order.

9: we use sheave drive,not cam .

10:when the the color sensor does not detect the target, or the mark is not in the right direction,the filling part does not fill this tube to avoid the wasting of the material.

11:Automatic tube filling and sealing machine . Valid and robust high speed tube filling machine. 12 station Cup-holder rotary table plate. Diving nozzle for a correct filling up from the tube bottom. CLOCKWISE rotation. Ergonomic tube loader. Quick format change over. Stable speed 65-75 tubes/ min.

Main Technical Parameter:

| Model | RGF-100B |

| Tube material | Metal tube,ALU tube |

| Tube diameter | Φ10- Φ32 |

| Tube length | 45-250(customizable) |

| Filling volume | 5-500ml/branch(adjustable) |

| Filling accuracy | ≤±0.5% |

| Speed (r/min) | 3-10 |

| Product capacity(pcs/min) | 65-70pc/min |

| Pressure | 0.55-0.65mpa |

| Motor power | 2kw(380V/ 220V 50Hz) |

| Power | 3.3kw |

| Overall domension(mm) | 2500×1200 ×2400 |

| Machine weight(kg) | 1500 |

Configuration lists:

| Name | Model | Brand |

| PLC | FX3GA-60MT/CM | Mitsubishi |

| Servo | SV-X3DA075A-D | HCFA |

| Motor | Taibang | |

| Inverter | FR-D720S-1.5K-CHT | Mitsubishi |

| AC contactor | LC1E3210M5N | SCHNEIDER |

| LC1E1210M5N | SCHNEIDER | |

| Switch power supply | DRO024V120W1AA | DELTA |

| Proximity switch | XS208BLNAL2C | Schneider |

| Touch screen | GS2107-WTBD | Mitsubishi |

| Encoder | E6BA-CW26C(1000) | OMRON |

| Colour photoelectric | Banner | |

| Temperature controller | DTK4848C01 | Omron |

| Pneumatic parts | FESTO | |

| Alarm light | Three color folding alarm light | SIEMENS |

| Plastic air plug | RS-114,RS014 | |

| Combination switch | HZ12-16/04 | |

| Stoke switch | LXW5-11Q1 | |

| Double jacket and water heater | ||

| Level sensor | Siemens | |

| 18 letters (Embossing) 000000 - 00/00 - 00/00 | ENGLISH FULL SET LETTER AND NUMBER | |

| contact part is 316L |